Heavy machinery such as industrial, mining, or farming equipment needs constant maintenance to keep it in good working conditions. Again, poorly maintained large machinery equipment will run inefficiently. Thus, if you have industrial equipment whether large or small, it is best to maintain them often to ensure they are in good shape for use. Safety is an important consideration for breakdowns are costly. Here are 5 top maintenance tips to extend your equipment life.

Table of Contents

1. Be on top of large machinery operator training

Most types of large machinery have multiple operators. So, any maintenance checklist for an ongoing inspection should be to oversee the correct operation of the equipment. Once you purchase any large machinery, ensure you inspect it immediately. At this point, operator training should be done, but training needs to be kept up. Since employees will come and go, skills can get rusty and with poor operation comes breakdowns. So, for specific workstations, have the operator manual revised. Have them written in simpler language. Every operator can have a short manual for easy reference. If your operations are paperless, ensure each operator has the most current version of each manual.

2. Check for signs of wear

In any heavy machinery, vibration, high temperatures, shock, friction, and age are factors contributing to the breakdown of parts. Vibrations are from belts and gears that are out of alignment. High temperatures come from friction, extended use, poor lubrication, and worn-out parts, among other things. The shock comes from poor operator technique and accidents. While age affects most key elements. Over time, seals will dry and crack, belts will warp, bolts become loose, and stretch out of shape. Therefore, age is a factor to keep in mind and monitor in any industrial equipment. Importantly, if you discover wear and tear on any moving parts within your equipment, ensure you quickly do the necessary replacement of those parts.

3. Test and add lubricants frequently

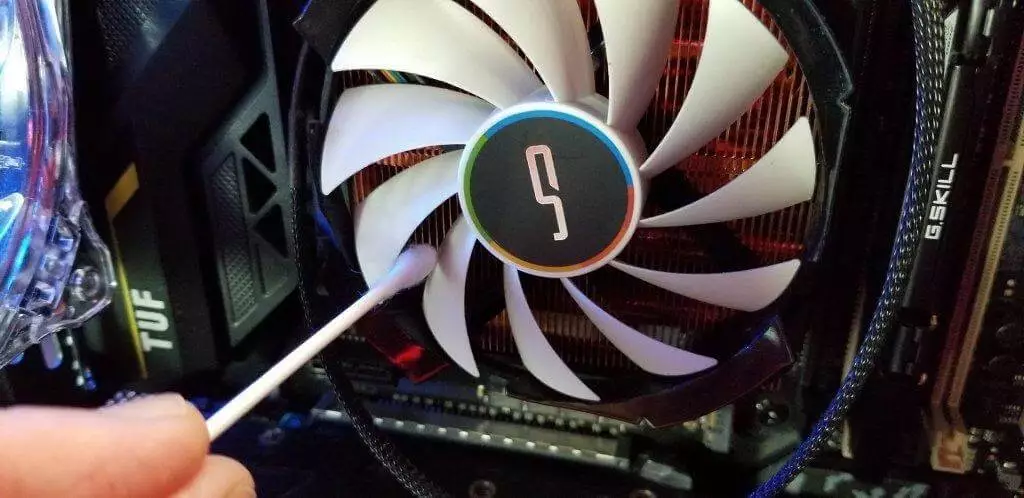

Lubricants help to reduce friction in moving parts. Therefore, having a routine of good lubrication maintenance will help extend the life of machinery parts and equipment. Lubrication should be among the most important and first maintenance checks. Check oil seals for any leaks. Importantly, ensure you use the right lubricant for there are specific kinds of grease and oil for every component. Check manufacturers’ recommendations. To diagnose problems with large machinery, ensure you have the lubricants checked. If you get experts, they can analyze particles in the used oil and this may indicate a part suffering from breakdown or wear.

4. Keep machinery clean, and maintain a clean environment

It is vital to keep working parts clean and free of contamination, as there are many seals and filters on heavy machinery to focus on during maintenance. Inspect seals regularly to ensure they are in good condition. Change and inspect filters often. Keep the breathers clean to avoid creating a vacuum in the cab which can suck contaminants into the cab. In terms of storage, store your large machinery in a shed or any other building where possible. Remember exposure to weather and wind can lead to rot and rust. Finally, ensure you run the machinery periodically if you are not using it.

5. Keep good records and a repair and maintenance schedule

Some of the components you need to check regularly in large machinery are the fluids, tracks, tires, and electrical systems for preventative maintenance purposes. Also, know what should be inspected and when. As an example, power transmissions have movable parts that need top maintenance. Seals, friction materials, gaskets, and bearings need to be checked for wear and replaced where need be. Change filters frequently and test the oil to diagnose possible problems. By checking bearings lubrication regularly, it will maintain it and extend life.

To conclude, following the above tips is vital to extend the life of heavy machinery significantly. Also, it improves the return of investments of these machineries. Nowadays, the global manufacturing world has more value if you have global knowledge in your company. In that, the knowledge of machinery maintenance is effectively shared across your organization. As a result, you reap more benefits on a wider scale.

Visit the rest of the site for more useful articles!